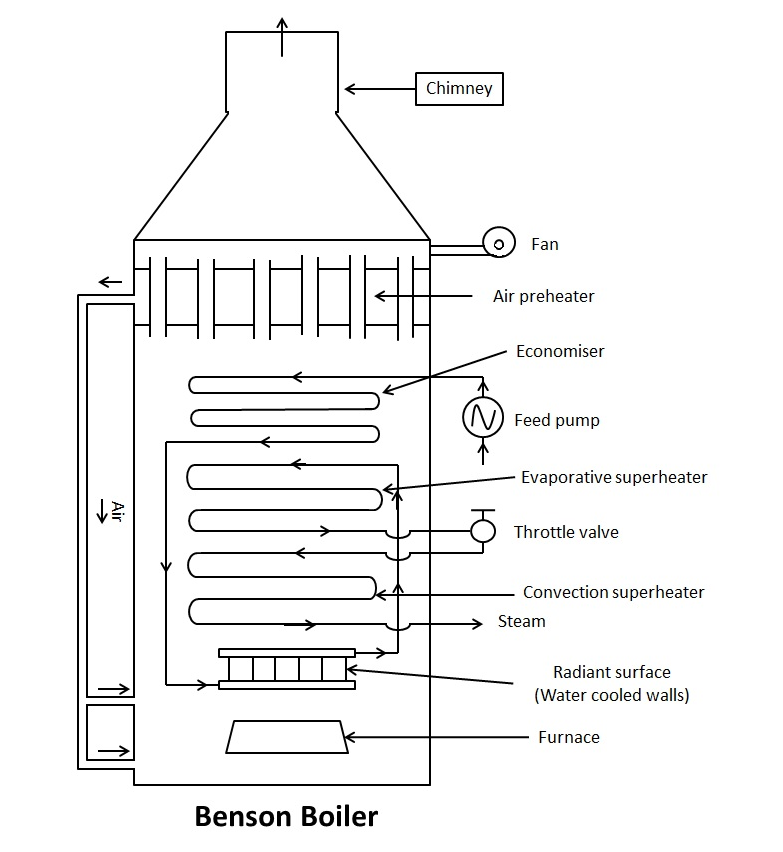

Benson Boiler Construction, Working Principle and Advantages with Diagram Mechanical Booster

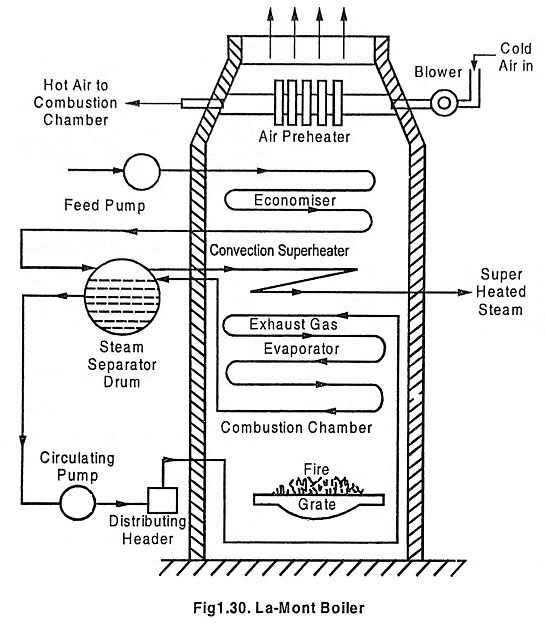

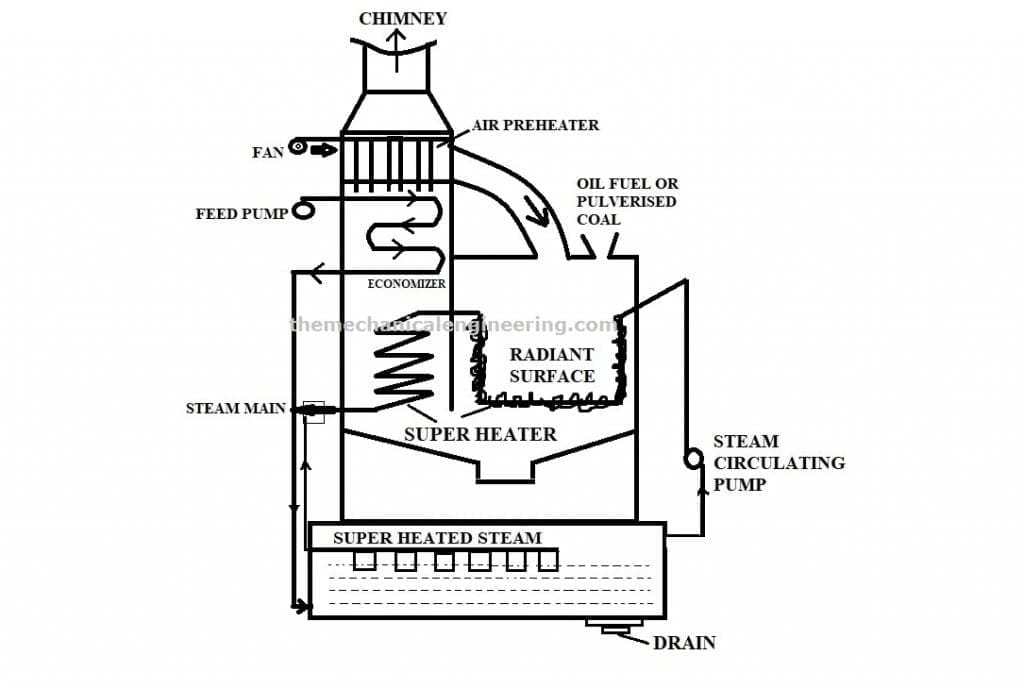

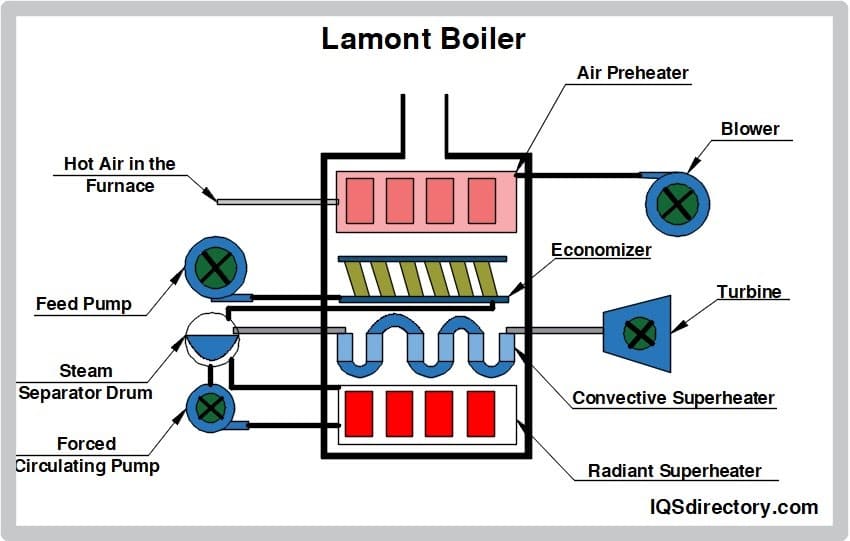

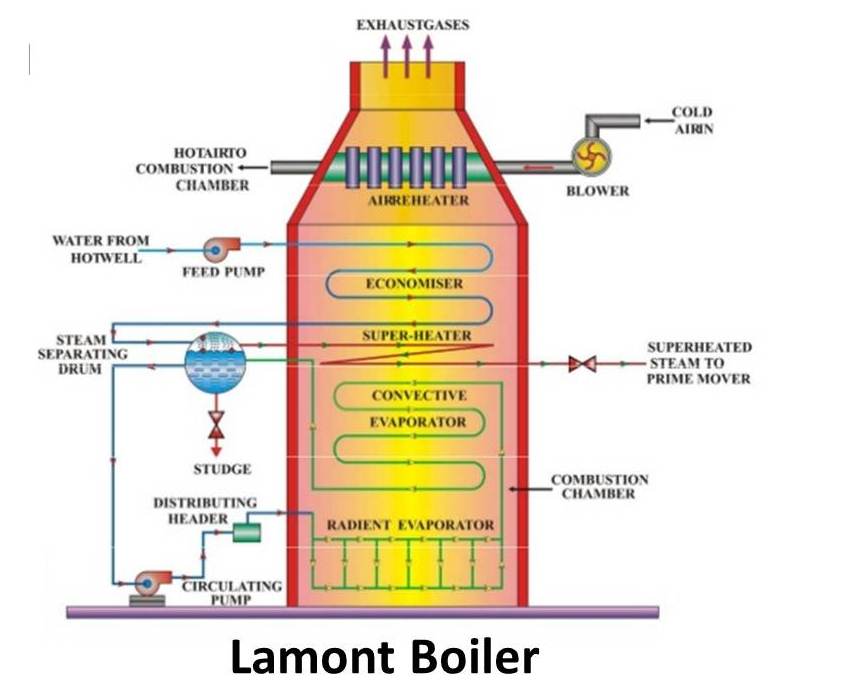

in Thermodynamics 0 Lamont boiler is a forced convection boiler. It is a vertical furnace water tube boiler in which the water flows inside the pipe tube and fire or flue gases surround them. Today we will study Definition, Parts, Working Principle Diagram, Application, Advantages, and Disadvantages of Lamont Boiler.

High Pressure Boiler, working, advantages and disadvantages Melezy

Subject - Thermal EngineeringChapter - Construction and Working of Lamont BoilerTimestamps0:00 - Start0:08 - Lamont Boiler0:28 - Construction of Lamont Boile.

Details 63+ boiler sketch seven.edu.vn

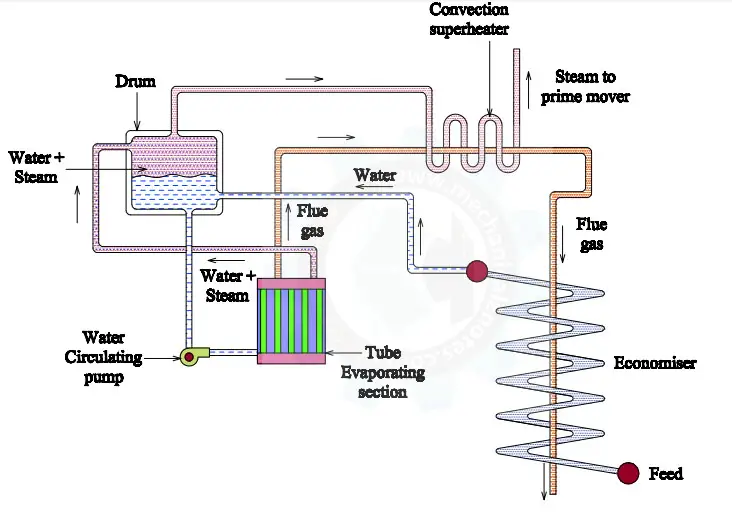

A LaMont boiler is a type of forced circulation water-tube boiler in which the boiler water is circulated through an external pump through long closely spaced tubes of small diameter. The mechanical pump is employed in order to have adequate and positive circulation in steam and hot water boilers.

Loeffler Boiler Definition, Parts, Working Principle, Types, Advantages, Disadvantages

The Lamont boiler is a type of water-tube boiler developed in the 1920s by Walter Douglas Lamont. It was designed to address the limitations of earlier boiler designs which used a force-driven circulation system allowing for higher steam production rates and improved efficiency.

Steam Boiler What Is It? How Does It Work? Types Of

The Lamont boiler is a type of forced circulation water tube boiler that uses an external feed pump to circulate the water in the small diameter of the water tubes. In this type of boiler, the water is circulated inside the water tubes while the flue gases surround these tubes. In 1925, Walter Douglas La-Mont invented the Lamont boiler.

Lamont Boiler Definition, Parts, Working, Advantages, Disadvantages & Applications [PDF]

Advantages: Constructions And Working Of Lamont Boiler | Application Lamont boiler is the first forced convection boiler which is introduce in the year 1925. A water circulating pump is used in the boiler to circulate water inside the boiler. This pump is driven by the steam turbine which uses steam of boiler.

High Pressure Boiler Manufacturers Suppliers

Detailed construction of following high pressure boilers are discussed in this video.1. LaMont Boiler2. Benson Boiler3. Loeffler Boiler4. Schmidt-Hartmann B.

Lamont Boiler construction and working notes Boiler type Water tube boiler Easy way English

Lamont Boiler Parts Of Lamont Boiler: These are the main parts of Lamont Boiler: 1) Feed Pump: Feed Pump supply water into the boiler from hot well. 2) Economizer: Economizer is used to increase the temperature of feed water to some extent. 3) Centrifugal Pump: Centrifugal pump is used to circulate water inside the Lamont Boiler as it is a forced circulation boiler.

WORKING OF LAMONT BOILER !! HIGH PRESSURE BOILER !! YouTube

In this article we will discuss about the design of LaMont boiler with the help of a suitable diagram. This boiler works on a forced circulation and the circulation is maintained by a centrifugal pump, driven by a steam turbine using steam from the boiler. For emergency an electrically driven pump is also fitted.

Lamont Boiler Main Parts, Working, Advantages and Disadvantages with Diagram Mechanical Booster

The Lamont Boiler is a type of forced-circulation water-tube boiler that was developed by Thomas C. Lamont in the early 20th century. This type of boiler is designed to be used in a variety of industrial applications, providing high-pressure steam, which can be used to power turbines, engines, pumps, and other mechanical equipment..

LaMont Boiler Diagram, Construction, Working, and Applications

Lamont boiler is a high pressure, forced circulation, water tube boiler with internally fired furnace. An external pump is used to circulate the water within small diameter water tubes of the boiler. This boiler was invented by Walter Douglas La-Mont in the year 1925. At that time this boiler was invented to use in ships. Working Principle

working principle of lamont boiler in telugu lecture YouTube

A LaMont boiler is a type of forced circulation water-tube boiler [1] in which the boiler water is circulated through an external pump through long closely spaced tubes of small diameter. The mechanical pump is employed in order to have an adequate and positive circulation in steam and hot water boilers. History

1. LaMont Boiler [4] Download Scientific Diagram

160+ million publication pages. 2.3+ billion citations. Join for free. Download scientific diagram | 6 High pressure Lamont boiler from publication: Basic Mechanical Engineering | Basic Mechanical.

Benson Boiler High pressure, Pressure, Thermal power plant

Lamont Boiler is a water tube boiler that has an internally fired furnace, high pressure, forced water circulation system. As I say, a forced water circulation system and for this reason, an external pump is used to circulate the water system within the small diameter water tubes of this boiler. Main Feature of Lamont Boiler:

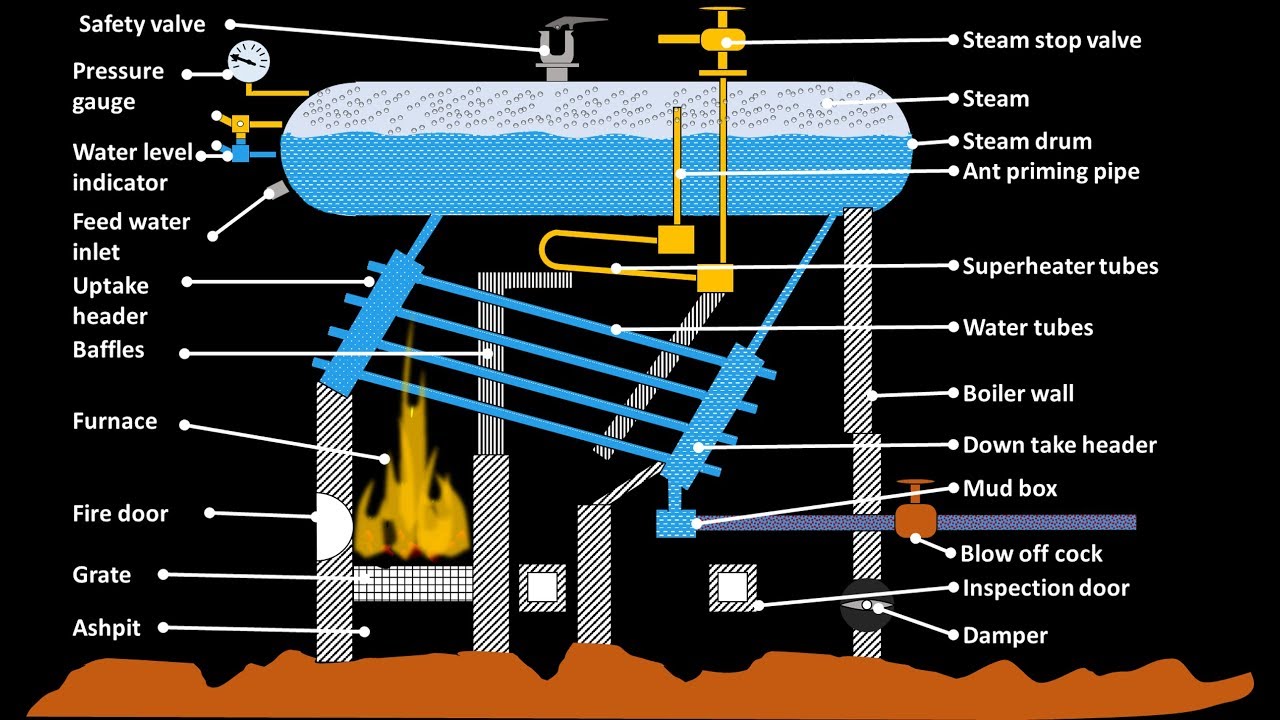

Babcock and wilcox boiler working animation simple diagram construction explained water tube

Test Series A LaMont boiler is a high-pressure, forced-circulation water tube boiler used for power generation. It is known for its efficiency and compact design. Invented by the American engineer and physicist Walter Douglas La-Mont in the early 1920s, this boiler design revolutionised the efficiency and safety of steam production.

Lamont Boiler Definition, Parts, Working, Application, Advantages [PDF]

1. Feed Pump A feed pump is used to drive the feed water at high pressure inside the boiler. 2. Furnace The vertical furnace is employed in the Lamont boiler. The principal function of the furnace is to burn solid fuel. 3. Grate The surface area of the grate, over which the fire takes place, is called the grate surface.