2008 Mi Swaco Shale Shaker Beeman Equipment Sales

Summary. A real‐time deep‐learning model is proposed to classify the volume of cuttings from a shale shaker on an offshore drilling rig by analyzing the real‐time monitoring video stream. Compared with the traditional video‐analytics method, which is time‐consuming, the proposed model is able to implement a real‐time classification and achieve remarkable accuracy. Our approach is.

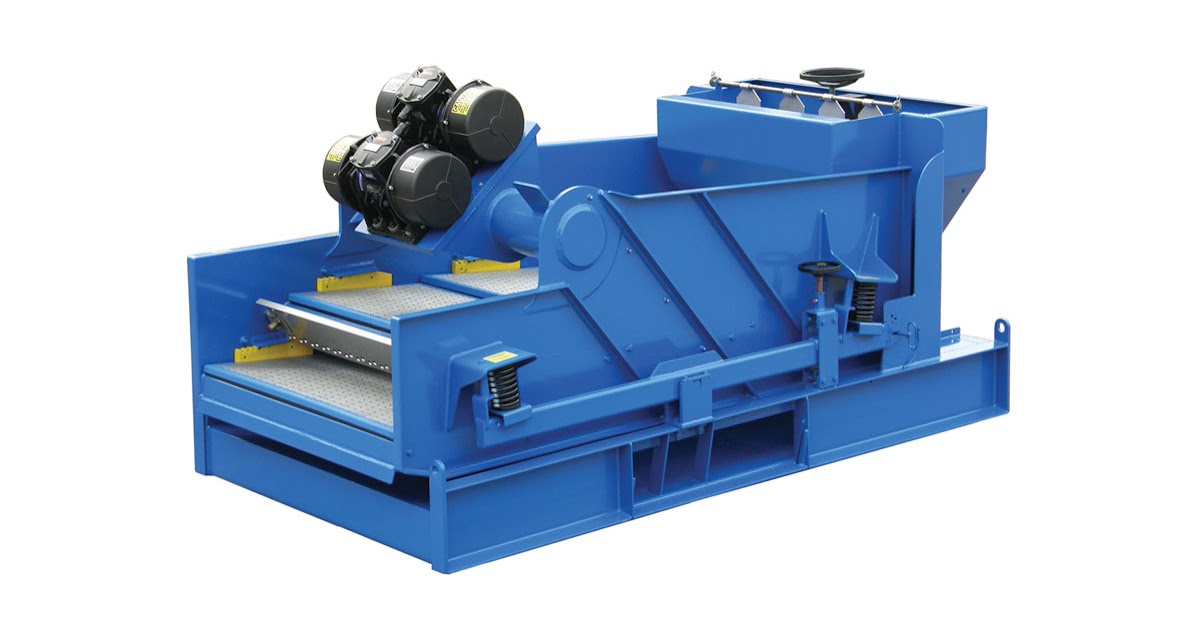

Shale Shaker Oilfield Drilling Mud Linear and Elliptical Double Track

Shale Shaker From: A Practical Handbook for Drilling Fluids Processing, 2020 Operating guidelines for drilling fluid surface systems Samuel Bridges, Leon Robinson, in A Practical Handbook for Drilling Fluids Processing, 2020 Operational guidelines for shale shakers • Shale shaker screens should not be by-passed while drilling or tripping pipe. •

Shale Shaker Oilfield Drilling Mud Linear and Elliptical Double Track

Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling.They are the first phase of a solids control system on a drilling rig, and are used to remove large solids ( cuttings) from the drilling fluid ("mud").

3= SKID MOUNTED SWACO SHALE SHAKER Beeman Equipment Sales

M-I SWACO suggested using MD-3 triple-deck shakers to meet the operator's drilling demands. The technology features three decks offered in a parallel or series configuration as well as automated deck-angle adjustments. Each shaker uses 18 screens that are less than 15 lb each, enabling faster and more simplified installation and changeout.

Shale Shaker on an Offshore Oil Rig. Shale Shaker Screen Close Up View

Basics of Shale Shakers Last Updated on Sat, 21 Oct 2023 | Drilling Fluids The characteristics of shale shakers are: (1) vibratory motion, (2) amplitude and frequency, (3) deck slope and number of decks of screens, and (4) screening area.

Shale Shakers on drilling rig YouTube

Shale shaker is first phase solids control equipment in drilling fluids processing system, also known as key solids control equipment in drilling mud system, shale shaker decides performance of the whole solids control system. GN Solids Control can design double shakers and triplicate shakerson single skid according to clients'special requirements and also supply relevant connecting manifold.

Dual Deck Tandem Shale Shakers Linear Motion For Onshore Drilling Rigs

SPECIFICATIONS RELATED PRODUCTS ATTACHMENT Utilize deck angle adjustment without requiring machine to be shut down or negatively affect operations Wedge type screen retaining system holds pre-tensioned screens in place during equipment operation Simple installation and removal. Sales & Spares Professional Contact TSC

Shale Shaker To Thailand GN Solids Control

The shale shakers are the first mechanical treatment of the returning drilling fluid for solids control. None of the other mechanical devices can cope with solids control without the pre-treatment of the mud in the shale shaker. A shale shaker or vibration screen is a spring-mounted screen.

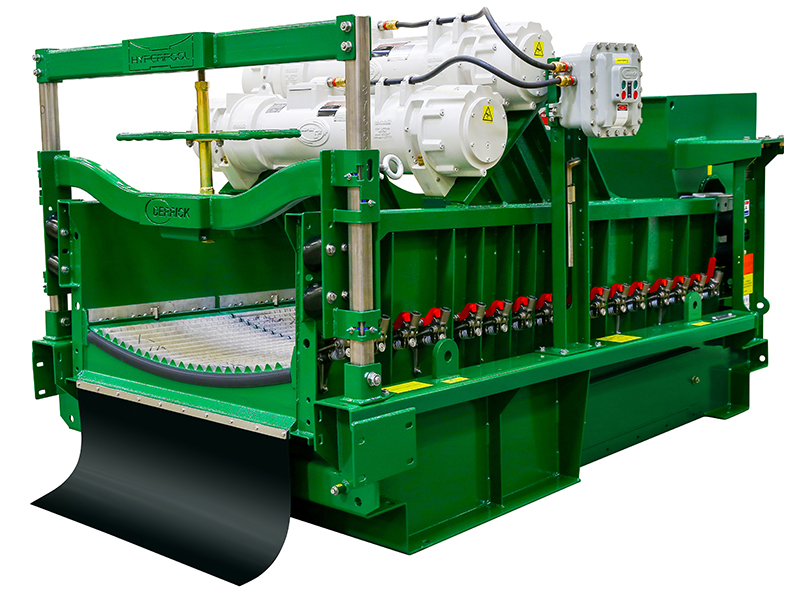

(2) DERRICK FLC503 Shale Shakers Beeman Equipment Sales

Shale shaker is the first phase of a solids control system on a drilling rig, and are used to remove large solids (cuttings) from the drilling fluid ("mud"). Shaker screen selection has the largest impact on the overall performance of the shale shaker.

Shale Shaker Drilling Oil Rig Hunter MG Series For Solids Control

Figure 1. Mud recycling (circulation) system. The three main shale shaker components are the hopper, the screen basket and the vibrator (Figure 2). The hopper, also known as the shaker base, serves as a collection pan for screened fluid, also known as underflow. The screen basket holds the fluid-sifting screens securely in place.

Drilling Knowledge What is Shale Shaker and the purposes

The purpose of shale shaker screening is to remove as much as possible of the drilled solids larger than the barite particles. In this manner bentonite, barite, and the liquid phase of the mud containing the chemicals are salvaged; the coarse, drilled solids are discarded.

OGEM Solids Control solids control equipment drilling fluid circulating

MONGOOSE Max High-capacity shaker Increase solids- and fluid-handling capacity by 35% and fluid recovery by 40%. View MD-3 Triple-deck shaker Meet objectives for efficiency, flexibility, and rig space with an adaptable shaker in a compact package. View SCREEN PULSE Fluid and cuttings separator

Shale Shaker On An Offshore Oil Rig. Shale Shaker Screen Close Up View

Shale shakers are the most important device on the rig for removing drilled solids from the mud. Without proper screening of the drilling fluid during this first mud processing step, downstream drilling fluid processing efficiencies and effectiveness are diminished. Operation Shale shakers are intensive vibrating devices.

2003 BRANDT KING COBRA Shale Shaker Beeman Equipment Sales

Awesome Prices & High Quality Here On Temu. New Users Enjoy Free Shipping & Free Return. Come and check All Categories at a surprisingly low price, you'd never want to miss it.

Derrick Hyperpool Series, solids control, shale shaker, solids removal

Shale shaker motors are generally three-phase induction motors that are explosion proof, having NEMA design B or similar characteristics (Table 17.10). The number of magnetic poles in a shale shaker motor can be four (1800 rpm synchronous shaft speed at 60 Hz), six (1200 rpm), or two (3600 rpm).

Shale Shaker On An Offshore Oil Rig. Shale Shaker Screen Close U

Frequency (rpm), stroke length. The vibrator frequency of most shale shaker designs is not normally adjustable. The vibrators typically rotate at a nominal RPM or 1200 or 1800 at 60Hz. Stroke length varies inversely with rpm. A higher rpm will result in a shorter stroke length at the same acceleration.