Terminations and Counterflashing Stopping Leaks Above the Roof Roofing

2-Piece. Carlisle's 2-piece Surface Mounted Counterflashing is easily installed by hooking and rotating the flashing to snap into the receiver. It provides a watertight termination at the leading edge of the roofing material. This reglet can be taken apart for easy roof repairs. Request A Quote.

Patent US6167660 Counter flashing Google Patents

Roof Materials Expenses Associated with Flashing Installations and Repairs. The national average cost to hire a roofer to replace the flashing, shingles, and to seal a leak in a small area of the roof is between $300 and $1,100. Larger roof fixes can cost between $1,100 and $1,500+. New Shingle Roof.

Quality Roof Detailing 101

TPO DETAILS Detail # PDF DWG Detail Name GF EZ TPO 1.01 PDF DWG Termination Bar GF EZ TPO 1.02 PDF DWG Termination Bar with Counter Flashing GF EZ TPO 1.03 PDF DWG Common Counter Flashing & Membrane Securement GF EZ TPO 1.04 PDF DWG Coping Termination Over Membrane Flashing GF EZ TPO 1.05 […]

What are the Different Types of Flashing? Your Own Architect

Counter flashing is very important anywhere you have brick on a home. This is usually on the roof and chimney areas. With this in mind, sometimes it is not installed or it wears out quickly and needs replacing. In general, the idea is to always keep water outside of the home. We will look at your chimney during home inspections in Chicago and.

19 Images House Construction Diagram

The flashing of the head of a batten seam roof at a wall is shown in this detail. The top of the roof pan is formed into a "bread pan" whose upper edge is just above the finished batten. Copper flashing is locked into this edge, and extends at least 8" up the wall. A copper receiver holds the counterflashing at its top edge.

Architectural Details Architekwiki

Two-piece counter flashing system with surface mounted reglet / receiver punched for fastening 12" on center. Snap-on metal skirt flashing can. reglet and flashing details are usually fabricated with an .050" (1.25 mm) reglet head and an .032" (0.80 mm) flashing. Special colors or finishes are available. Finish setups

Pin on Week 6 Dream Team

2-Piece. Carlisle's 2-piece Surface Mounted Counterflashing is easily installed by hooking and rotating the flashing to snap into the receiver. It provides a watertight termination at the leading edge of the roofing material. This reglet can be taken apart for easy roof repairs. Request A Quote.

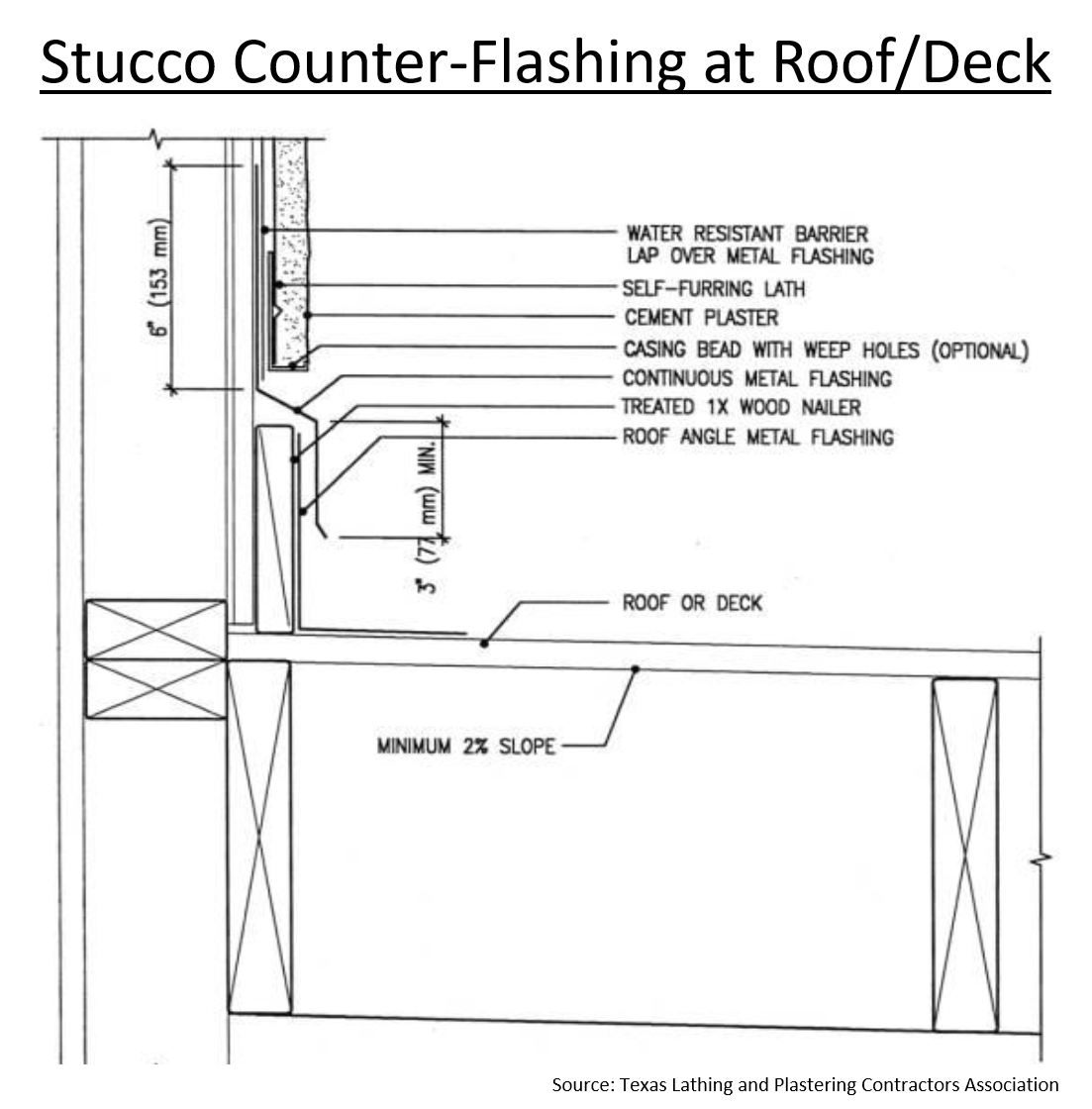

Stucco Construction Details Builder Academy

Everybody Needs a Roof: Base Flashing. Counter flashing is the final layer of a three-part waterproof barrier installed between a roof and a vertical wall or chimney. The first two layers are called base flashing and step flashing. The term reglet flashing refers to an installation method for counter flashing, not a separate layer.

2 Piece Counter Flashing Architectural Products

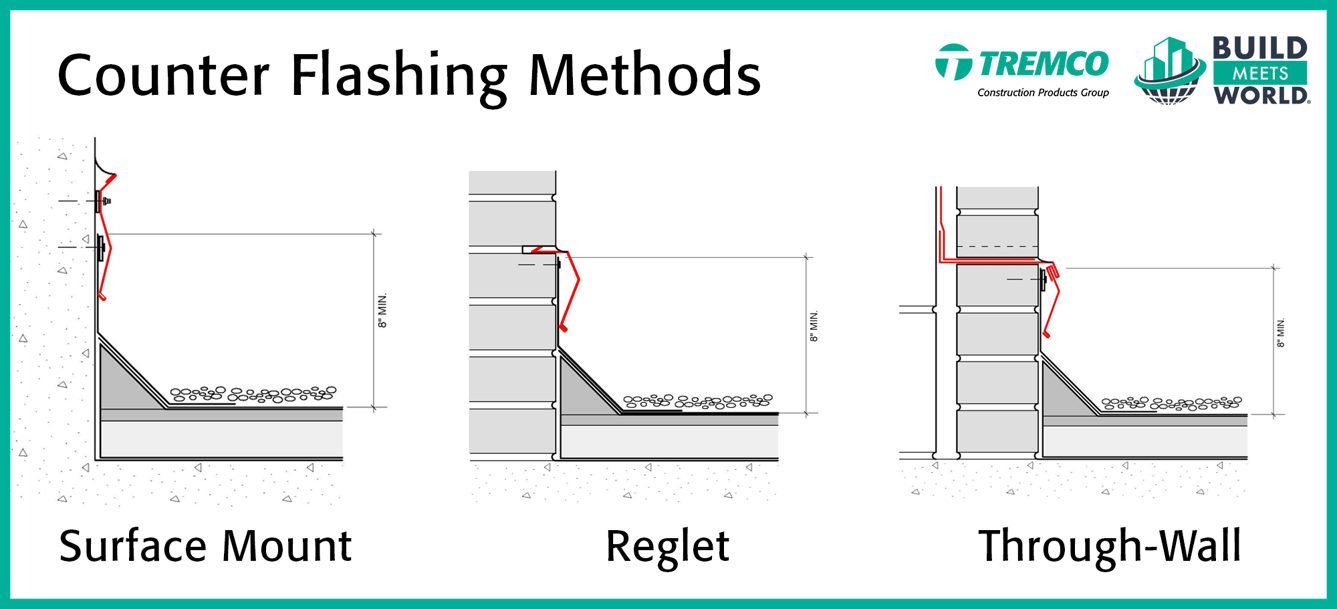

Counter Flashings. ATAS offers two styles of Counter Flashing; a 2-piece system with receiver and snap-in skirt, or an economical 1-piece system. Both the 2-piece and 1-piece counter flashings are available as surface mount, reglet, or through wall. Counter Flashing is provided in 12′-0″ lengths, pre-punched for fasteners, and is available.

Surface Mounted Counter Flashing

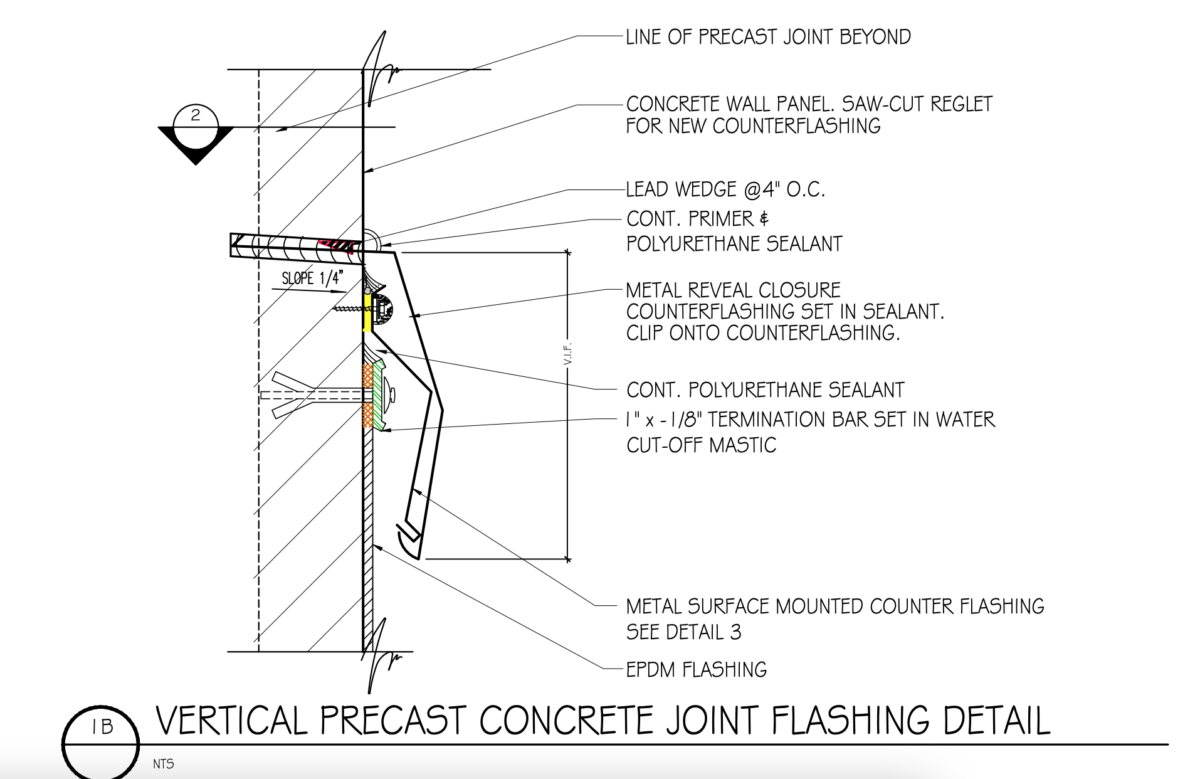

Securement. Counterflashings are secured in their reglets with lead wedges (rolled, 4-pound lead sheets) tapped into position to create a friction fit. Lead wedges typically are spaced 12 inches on center and a minimum of two per counter-flashing. If the counterflashing moves under hand pressure, add wedges as needed.

Flashing Details Counter Flashing with Kick Out ARCA Construction

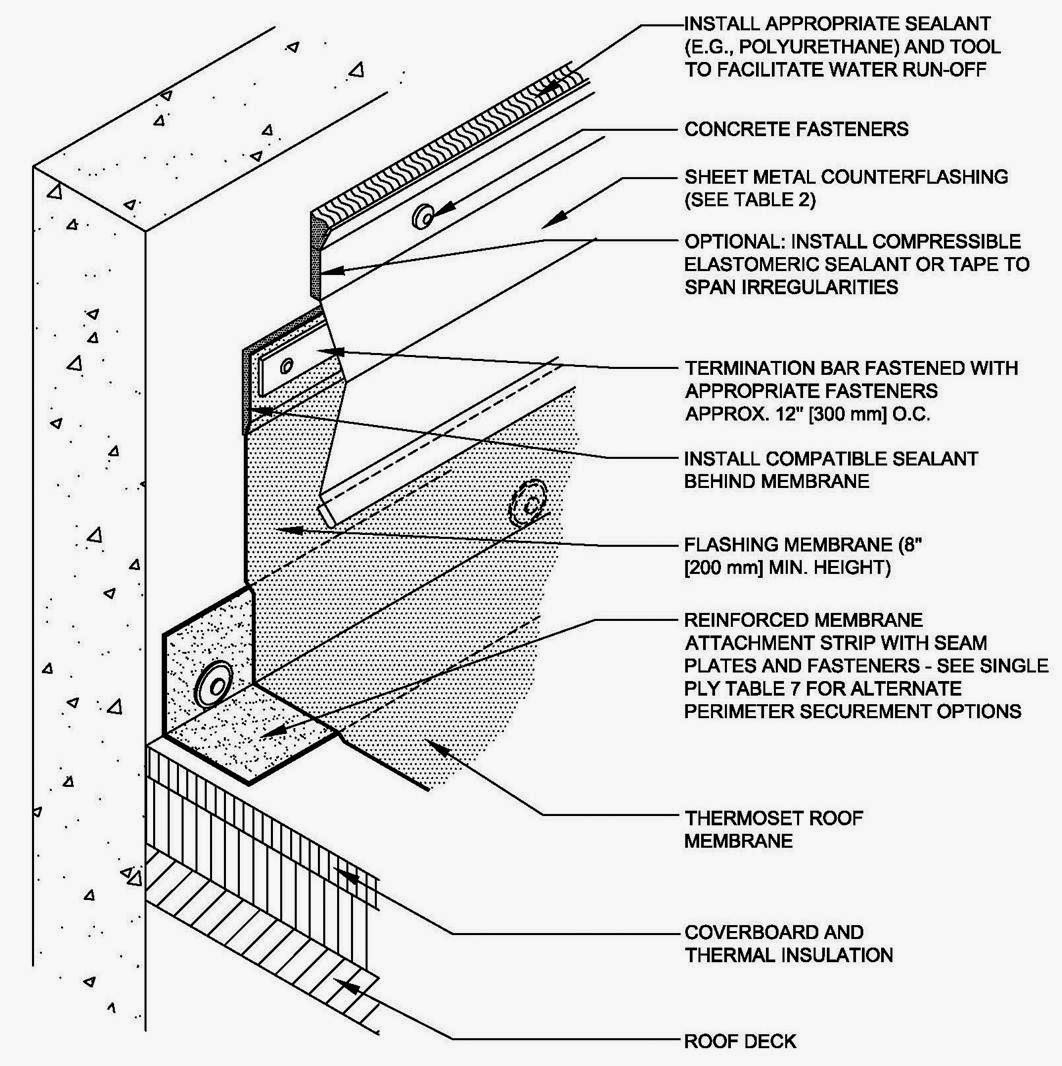

Roof to Wall Flashing: Why Details Matter for Single-ply Roofing Systems. Roof to wall flashing is critical to the performance of every single-ply roofing system. These transition points, where the flat part of the roofing system is tied into the parapet wall, are potentially vulnerable areas for water intrusion.

Patent US6108981 Surface mount counter flashing system Google Patents

Weep holes or open head joints should be located a maximum of 32 in. (813 mm) apart. Flashing at lintels and sills (shown in Figures 2 and 3, respectively) is very similar. Although not shown, vents can be installed in the vertical head joints at the top of masonry walls to provide natural convective air flow within the cavity to facilitate.

Roof Tech Talk January 2014

The Gibraltar Counter Flashing is made from trusted 30-Gauge galvanized steel. It is designed to cover and protect the top edge of step flashing used on chimneys. The top bend in the flashing pressure fits into a saw kerf made into the chimney, the lower bend forms a grip edge that fits securely against the step flashing.

Roofing Reglet & Roofguard » FORTIFABRIC Sc 1 St Roof

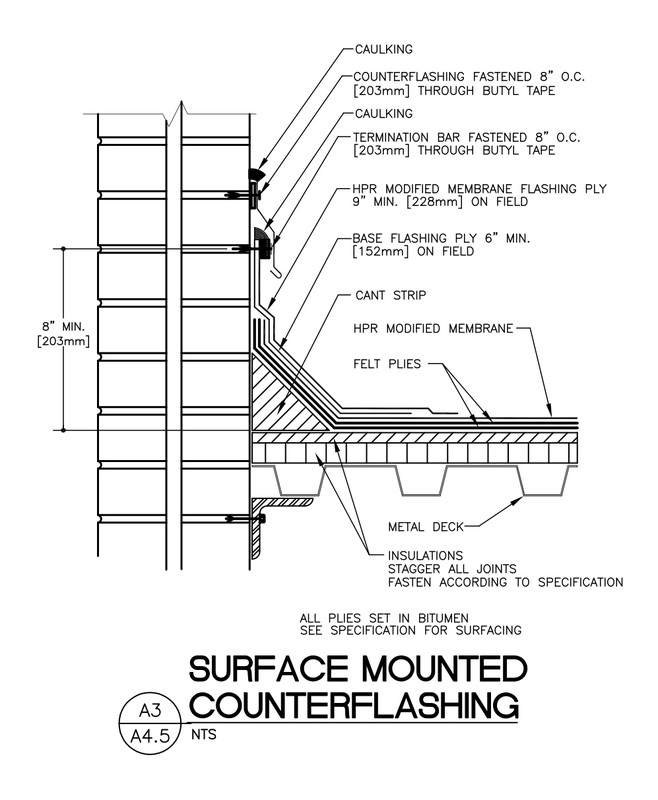

For continuity of a sealing mastic between the substrate and membrane, consider designing and detailing the use of a continuous 3/16" x 1" butyl caulk tape. The butyl will fill in the concave vertical brick mortar joints. 5. Mandate that the termination bar is to be installed on the same day at the base flashing. 6.

Counter Flashing Architectural Products

Title: 3-3A Surface Mounted Counter Flashing Detail Author: Sika USA Created Date: 2/4/2019 2:13:52 PM

Patent US6167660 Counter flashing Google Patents

Base Flashing 2PC Counter Flashing-Base Flashing. Detail Drawing (PDF) DWG - 244 KB (en) Edge Metal Flashing. Detail Drawing (PDF) DWG - 241 KB (en). Flashing Details PDF Files. PDF Files. LAM Overflow Drain Flashing. Detail Drawing (PDF) PDF - 206 KB (en) LAM Thru Wall Duct Flashing.